Definitions

Load: Load is a criterion which gives a clear picture about the strength of a material. It is an external pressure or impact offered against the inter molecular bond of the object which results in deformation (or fracture) of the object.

Stress: The intensity of the resisting force offered by the inter molecular bonding of the object per unit area towards the load applied before the failure of the object is called as stress.

Generally stress is represented as c or f

Hence σ = P /A or W /A (Since P=W)

Where P= load applied, W= bond resisting force , A = area of cross section of the material.

SI units of stress are N/mm2, N/m2, N /cm2

Note:

CONVERSIONS

|

CONVERSIONS |

|

|

1kg |

10N |

|

1m |

1000mm |

|

1m |

100cm |

|

1cm |

10mm |

|

1mm |

0.1cm |

|

1mm |

0.001m |

|

1cm |

0.01m |

|

1pa |

1N/m2 |

|

1GN |

109N |

|

1MN |

106N |

|

1GN |

103N |

|

1N/mm2 |

106N/m2 |

Strain: When the object is subjected to the external force, initially at the equilibrium condition (P=W) the deformation effect is negligible. But with the gradual increase in the magnitude of the applied load, the dimensions of the object will be altered due to the deformation effect. Therefore the ratio of change in the dimension (due to deformation effect) of the object to its original dimension (at equilibrium condition) is termed as strain of the object.

Strain is a unit less quantity.

TYPES OF STRESS AND STRAIN :

Tensile stress and tensile strain

Consider a uniform bar of cross sectional area A subjected to an axial tensile force P. The stress at any section x-x normal to the line of action of the tensile force P is specifically called tensile stress. Since internal resistance R at x-x is equal to the applied force P, we have,

Tensile stress = (internal resistance at x-x)/(resisting area at x-x)

= R/A

= P/A.

Where,

P=Tensile load

L =Original length

dl=Elongation

L+ dl=Increase in length with respect to original length

Under tensile stress the bar suffers stretching or elongation. Therefore ratio of increase in length to the original length is termed as tensile strain.

Compressive stress and strain

If the bar is subjected to axial compression instead of axial tension, the stress developed at x-x is specifically called compressive stress.

Compressive stress = (internal resistance at x-x)/(resisting area at x-x)

= R/A

= P/A.

Where,

P=Compressive load

L =Original length

dl=Shortening

L- dl=Decrease in length with respect to original length

Under compressive stress the bar suffers shortening. Therefore ratio of decrease in length to the original length is termed as compressive strain.

Shear Stress

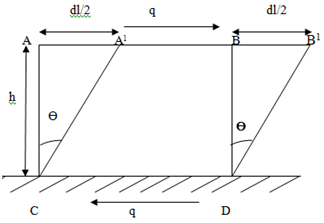

The stresses set up at the section x-x acts along the surface of the section, that is, along a direction tangential to the section. It is specifically called shear or tangential stress at the section and is denoted by q.

q = R/A

= P/A.

Where,

Shear strain ϴ =Transverse displacement/Distance AC= (dl/2)/h

Tan ϴ= ϴ (since it is small)

0 Comments